Innovating Cleanroom Excellence

×

×

The Embassy Group, one of India’s leading infrastructure partners and developers, is renowned for constructing top-quality commercial and industrial premises. They worked with Kaizen Airtreat on the present project, which involved installing a modular cleanroom system at an automobile manufacturing plant of good standing and repute in Chakan, Pune.

With a mandate to cause minimum disturbance to the current activities, the project’s scope included the design, engineering, supply, and installation of a cleanroom enclosure along with its associated HVAC system, electrical integration, and all the relevant cleanroom components.

The aim was to provide a contamination-controlled environment for component testing and high-precision assembling. The latter, in the case of automobile manufacturing, involves precision testing and sensitive assembling, where minor contamination can adversely affect product performance, leading to product failure in real-world use.

To address these challenges, the client needed a solution that offered rock-solid control over temperature, humidity, and airborne particle ingestion while ensuring compliance of the facility with ISO Class 8 standards, all without disrupting the facility’s ongoing production activities.

Materials chosen for the project met compliance standards while offering performance, durability, and ease of installation,

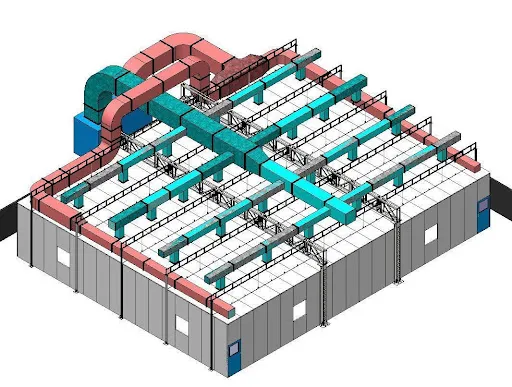

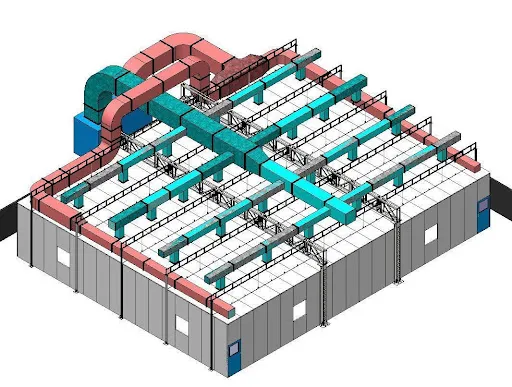

In a normal working environment, a typical turnkey cleanroom project has four main sections, namely the enclosure, the HVAC system, the electricals, and miscellaneous items. In the present case, we used PUF panels of 50 mm thickness to eliminate the possibility of heat transfer to insulate the enclosure. We used AHU and HEPA filters in the HVAC system for air filtration and maintaining the required humidity and temperature.

Ultimately, equipment that formed part of our offering included Air Showers, Smoke Detectors, Lights, and a Boom Barrier. To cater to the power load of the final equipment and the project, we used a customised control panel.

The goal was to implement a cleanroom system to create a controlled environment that complied with ISO Class 8 standards and supported processes like component testing and precision assembly. In this case, while the mandate regarding its usage was reasonably clear, what added to the complexity was a strong focus on minimising disruption to the existing operations.

With the client approving our designs, Kaizen Airtreat’s engineering and execution team initiated a structured implementation plan with each stage being focused on functionality, compliance, and integration, all taking place within the space of an active manufacturing site. Components of our primary offering thus included the following,

The Kaizen Airtreat’s approach towards tough quality control framework involved the following,

The structural framework and cleanroom integration at the customer were first validated using,

The successful installation of a cleanroom for the Embassy Group was of special importance as it showed Kaizen Airtreat’s ability to successfully execute the project within a running automobile facility, which meets ISO Class 8 standards, without disturbing ongoing operations. The solution that was provided brought about a contamination-free environment for precision testing and assembly. With the combination of efficient installation, integrated systems, and future scalability, the setup now supports the client’s high-performance manufacturing needs and will do so for quite some time.

We specialise in providing Turnkey Solutions, including Designing, Engineering, Procurement, Construction, Commissioning, Validation, and FEED services, including operation & maintenance of cleanroom and HVAC systems that cater to diverse industries such as Automotives, EVs, Semiconductors, Pharmaceuticals, Healthcare and Medical, Electronics, Aerospace, and the Food industry.

We specialise in providing Turnkey Solutions, including Designing, Engineering, Procurement, Construction, Commissioning, Validation, and FEED services, including operation & maintenance of cleanroom and HVAC systems that cater to diverse industries such as Automotives, EVs, Semiconductors, Pharmaceuticals, Healthcare and Medical, Electronics, Aerospace, and the Food industry.

WhatsApp us