Innovating Cleanroom Excellence

×

×

The Coca-Cola Company, one of the world’s leading beverage brands known for its products, including the world’s most well-known soft drinks, has other products to its credit, including beverages based on plant and fruit extracts, and even tea and coffee. Besides its product line-up, the company is known for its high standards of product quality, which comes from its use of hygienic means of production that increase the chances of food safety in almost every circumstance.

Beverage formulation, bottle filling, capping, labelling, packaging, and quality inspection are important processes at the Coca-Cola bottling plant in Riyadh. Of these, the bottle-filling procedure requires a significantly regulated and clean environment, the absence of which can compromise the beverage’s quality, flavour, and shelf life, with dust, airborne particles, and bacteria being some of the known contaminants.

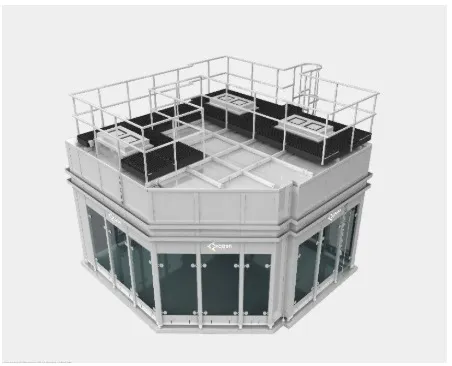

Coca-Cola Riyadh thus wanted an ISO Class 7 cleanroom enclosure that would help its production facility maintain clean air conditions, directly and positively affecting the integrity of its products, making them compliant with the food safety laws of countries where these products would be consumed.

Kaizen Airtreat was responsible for designing, manufacturing, and shipping a ready-to-install Modular Clean Room for Beverage system from India, meeting Coca-Cola Riyadh’s high production and product standards. The project was quite big, as it involved supplying an entire enclosure, HVAC systems, electricals, and supporting works & products that would be assembled at the destination to come up with a working cleanroom. To sum up, key requirements included,

The materials chosen for the project underwent strict inspection to match with compliance laws abroad, besides being functional, assisting cleanliness, and promoting easy integration. Each component served a specific role,

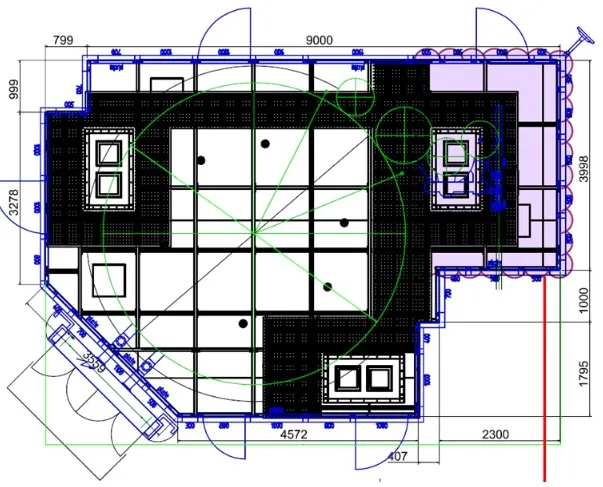

With the project getting the client’s green signal, Kaizen Airtreat’s design team went about designing a modular cleanroom system that was tailored entirely to the client’s plant layout and needs. Since the site was outside India, client-supplied drawings were of crucial importance in manufacturing the plant. In the end, what was supplied included,

Once the design was finalised by the buyer, i.e., Coca-Cola Riyadh, the cleanroom was entirely fabricated and pre-assembled at Kaizen’s facility in Pune. The process included the following tests and checks

– Structural load tests for the ceiling truss system

– Door sensor performance checks

-Visual inspections and surface finish approvals

To simplify the installation process, especially at an overseas location, each part was clearly labelled, and a comprehensive step-by-step installation manual was created. The entire system was then securely packed and shipped to Saudi Arabia in sea-worthy packing. At the intended destination, the cleanroom was successfully installed and commissioned, attesting to Kaizen Airtreat’s expertise.

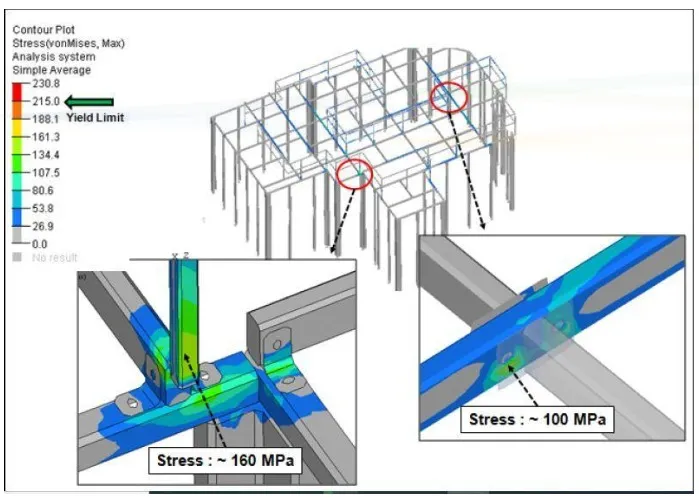

To ensure safety and reliability, structural validation included

The project highlights Kaizen Airtreat’s capability to deliver high-quality, custom-engineered Modular Clean Rooms for beverages to any location globally. Meeting Coca-Cola’s strict hygiene, safety, and operational needs, our cleanroom solution showcases our commitment to excellence in projects that match international standards. As of now, the cleanroom continues to support efficient and contamination-free bottling at Coca-Cola’s Riyadh facility.

We specialise in providing Turnkey Solutions, including Designing, Engineering, Procurement, Construction, Commissioning, Validation, and FEED services, including operation & maintenance of cleanroom and HVAC systems that cater to diverse industries such as Automotives, EVs, Semiconductors, Pharmaceuticals, Healthcare and Medical, Electronics, Aerospace, and the Food industry.

We specialise in providing Turnkey Solutions, including Designing, Engineering, Procurement, Construction, Commissioning, Validation, and FEED services, including operation & maintenance of cleanroom and HVAC systems that cater to diverse industries such as Automotives, EVs, Semiconductors, Pharmaceuticals, Healthcare and Medical, Electronics, Aerospace, and the Food industry.

WhatsApp us